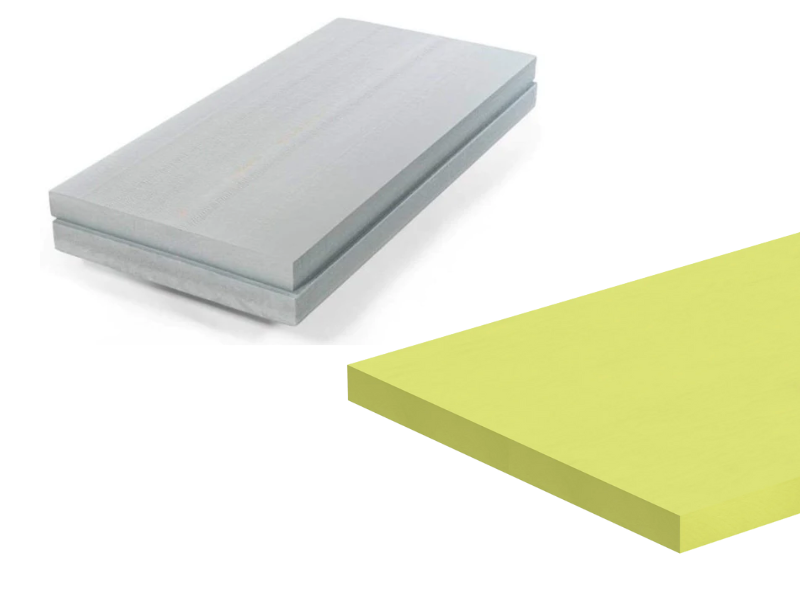

Polystyrene is a versatile synthetic polymer used in a variety of applications. It is incredibly useful because it is inert (doesn’t react with other materials), lightweight, cost-effective, and long-lasting. As a hard, solid plastic, it’s utilized in laboratory ware, automotive parts, appliances, food packaging, and electronics. Polystyrene is also made into insulating foam materials, called expanded polystyrene (EPS) and extruded polystyrene (XPS), which is valued for its high level of thermal efficiency and strength-to-weight ratio.

XPS foam boards are the most popular when it comes to high-quality insulation for roofing, below-grade applications, commercial and recreational vehicle insulation, and more. This is because it features a closed-cell construction, making it highly water-resistant and capable of performing well as an insulator even in the most challenging situations.

What Does Closed-Cell Mean?

XPS foam insulation is a closed-cell insulation, meaning there are no tiny voids or spacing between the polystyrene cells. This is achieved through a manufacturing process that involves extruding the polystyrene through a die. EPS foam, on the other hand, is produced by expanding the polystyrene cell, which can lead to tiny, irregular gaps.

Having a completely closed-cell construction is essential for reducing heat transfer and makes XPS foam highly resistant to water absorption and water vapor transmission. This means it can maintain low thermal conductivity in the presence of a lot of water, making it uniquely suited for applications such as building foundations, underground walls, inverted roofs (including terraces and green roofs), cold storage facilities, and parking lots.

High-Performance Insulation for Construction

In commercial construction, rigid foam insulation needs to meet a trifecta of requirements – thermal insulation performance, durability, and economics. XPS foam as insulation can save approximately 200 times the amount of its embodied energy through its ability to increase the building envelope efficiency. It also has the compressive strength characteristics needed to be used in load-bearing floors, which is important as floors are a huge source of thermal transfer.

A closed-cell insulation material like XPS foam can resist freeze-thaw cycles, ensuring long-term durability at a relatively low cost. Moisture that gets into tiny gaps of EPS foam insulation will shrink and expand as it goes through the freeze/thaw cycle. This significantly impacts its performance as an insulator on top of causing early deterioration. XPS foam insulation is water-repelling and capable of withstanding over 1000 freeze/thaw cycles.

Improve Energy Efficiency in Buildings

The homogeneous closed-cell composition of XPS foam insulation prevents heat transfer and air leakage. Energy losses caused by air leaks and a poorly insulated building can have a significant negative impact on heating and cooling costs. In both summer and winter, XPS foam insulation boards can regulate a consistent temperature inside a building over a long period, regardless of whether conditions are wet or dry.

XPS foam insulation has a consistent long-term thermal resistance even in wet conditions and at low temperatures. It maintains its thermal and mechanical performance throughout the life of the building. It is incredibly durable and has a high compressive strength for heavy and dynamic loads.

Features of XPS insulation

- Extremely durable

- Capable of bearing heavy loads

- Highly resistant to moisture

- Guaranteed to have a low, stable, and predictable thermal conductivity

- Able to withstand the stresses of temperature changes and freeze/thaw cycles.

See our XPS boards here: